Living in a data driven, internet connected world means that trying to stay on top of the game is often two-fold for many manufacturing companies. Not only does internal production need to be beating off competitors in terms of speed, quality and price; but the external appearance of the company must put them at the top of search engines, in front of the right people and constantly regenerating to make customers see them the way they wish to be seen.

In the last few years there’s been a ‘Big Data’ surge in the manufacturing world. While it sounds like a wrestler’s ring name, it’s actually a term for data that’s bigger and harder to translate than the usual data (we want to say small data, but sadly it’s not – it’s simply ‘data’). Previously used by more ‘refined’ industries such as hospitality and retail to get instant and concise information, manufacturers have started to reap the benefits of immediate insight into their production and methodology.

But what does ‘Big’ Data do that ‘Data’ Data doesn’t…?

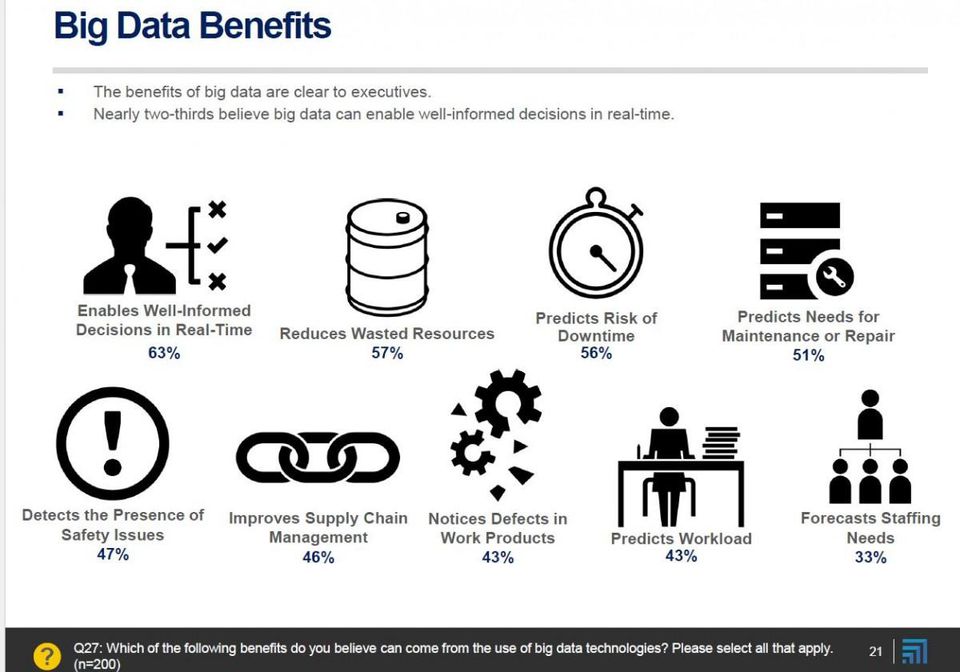

Big data helps unlock patterns, identify performance and loss, and introduce feedback into production methods that simply hasn’t been possible before. Manufacturing is often an area that reeks of an ‘if it ain’t broke, don’t fix it’ attitude. We live in a competitive, dog eat dog world which means that this sort of stagnant attitude will quite likely kill off age-old businesses that refuse to change with the times when their competitors are offering more for less and at a quicker speed. And they can do all this because they’re using Big Data to see their product – in depth, further down the line, how it is used and by whom, and then taking this information and using it to refine and improve their product. Just take a look at this brilliant infographic by Forbes to see the insights Big Data can offer.

But Sugar doesn’t even do ‘Big Data Analytics’!?

This is very true, but as a business development agency, we see so much of what we do in Big Data – it resonates on many levels and we LOVE analytics, just analytics of the Google kind. We look at the manufacturing process further down the line so, while we can’t recognise when a machine in the factory is slowing down the entire process like Big Data can, we can recognise when a word in an advert is affecting the click through rate and change it accordingly. Seemingly a small correction but could be the difference between thousands of clicks and none. Both tools are important to the overall success of the company – and one without the other seems futile. Why polish the trophy then put it in a smeary cabinet so it can’t be seen?

We seek feedback from clients and translate it into click worthy content. And we use Search Engine Optimisation to get the manufacturers ranked higher by using that content in a way we know Google will recognise as worthy and relevant to enhance their position. Research, experience, knowing what to look for, and knowing what to write to enhance the business outwardly – the tools that as a business development agency we bring to the manufacturer – are in so many ways what Big Data does internally: being the nuts and bolts and improving the quality and production at grass roots level.

Imagine if, as a business, you did both?